Wagner Powder painting equipment, 2010

Wagner Powder painting equipment, 2010

Contact us for price

Description

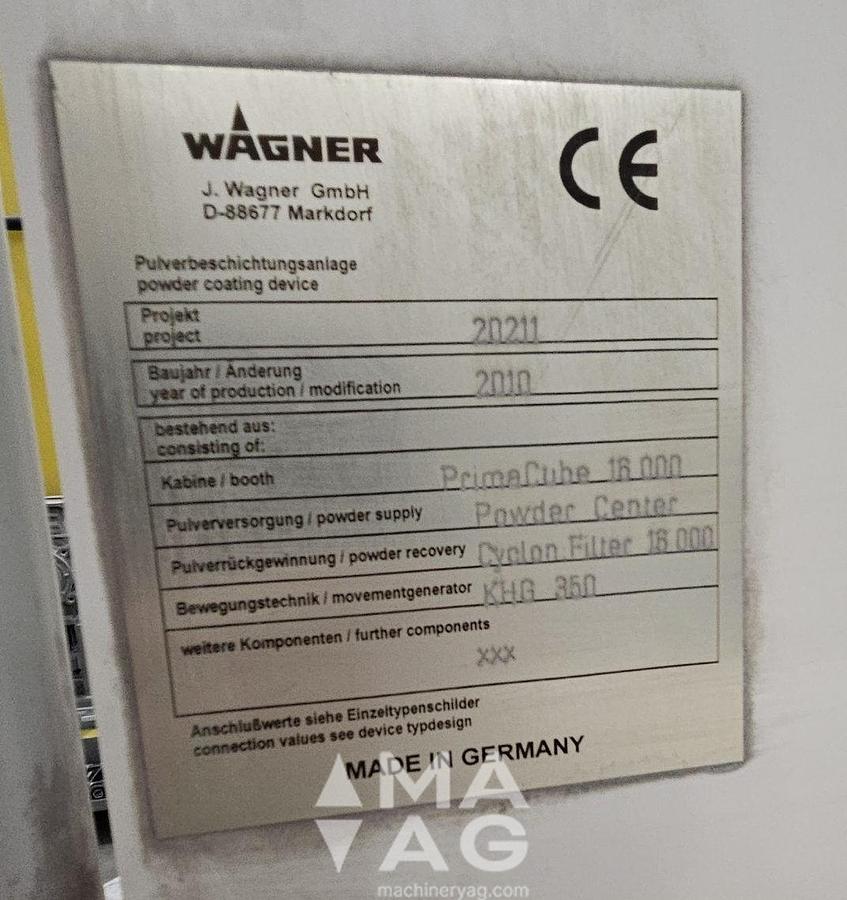

Wagner Powder painting equipment for sale!

Powder coating device, year 2010 consisting of:

Booth: Prima Cube 16000

Powder supply: Powder Center

Powder recovery: Cyclon Filter 16000

Movement generator: KHG 350

Production process configurations INCLUDING:

I. Presumes

Maximum size of parts: LxWxH=2600x400x1850 mm

II. Equipment

Technological Conveyor automatic speed V=1.2 mtrs/min.

Speed regulation between 0.5-2.5 mtrs/min

1. Pretreatment Stand MNA-3-LPG, total size 16,7 mtrs

Enter size L=2,5 mtrs

a. Washing, degreasing and phosphating; L=3,6 mtrs

-number of spray frames – 10

-number of nozzles in frame – 18

-number of nozzles in total – 180

-delivery of the pump – 162 m3/h

-power of the pump – 15 kW

-vessel 4 m3 for active liquid

-inner heat exchanger with LPG burner – 160 kW

-temperature 500C

-mechanical oil separator

- solution filter

-the dosing system, membrane pump with regulator

-washing time – 3 min

b. Dripping zone L= 3,1 mtrs

-time of dripping – 2 min 30 sec

c. First rinsing; L= 1,2 mtrs

-number of spray frames – 4

-number of nozzles in frame – 18

-number of nozzles in total – 64

-delivery of pump – 38 m3/h

-power of the pump – 3 kW

-vessel 1,5 m3 for water

-first rinsing time – 1 min

c. Dripping zone L= 3,1 mtrs

-time of dripping – 2 min 30 sec

d. Fine rinsing; L= 1,28 mtrs

-number of spray frames – 3

-number of nozzles in frame – 18

-number of nozzles in total – 54

-delivery of pump – 33 m3/h

-vessel 1,5 m3 for water

-power of the pump – 3 kW

-one extra spray frame

-number of nozzles in frame – 18

-fine rinsing time – 1 min

e. Dripping zone L= 2 mtrs

-time of dripping – 1 min 40 sec

Three openings to connect to exhaust system with three ventilators

Operating space made of stainless steel.

Pipes made of PVC or S/S.

1 unit

2. Automatic Dryer after water AST-1-KLPG:

- operating space dimensions LxWxH=7000x3000x2800

- air curtains each side to avoid heat losses

- one indirect heat exchanger heated with liquid petrol gas to produce 200 kW of rated power

- three blowers 6000 m3/h of air delivery

- two openings to connect to exhaust system

- temperature sensor and temperature regulator

- overheating sensor

- circulation sensor

- operating space made of zinc plated steel

- thermal insulation 200 mm thick

- drying time 10 min

1 unit

3. Automatic Curing Oven APT-2-KLPG for curing powder paints

- operating space dimensions LxWxH=10200x3600x2800

- air curtains on one side to avoid heat losses

- two indirect heat exchangers heated with liquid petrol gas to produce 300 kW of rated power, of each

- eight circulation blowers, capacity of each 6 000 m3/h

- two openings to connect to exhaust system

- temperature sensor and temperature regulator

- overheating sensor

- circulation sensor

- operating space made of zinc plated steel

- thermal insulation 200 mm thick

- curing time 25 min

1 unit

4. An overhead rail conveying system ATR-ADAX, for the paint shop including the following:

• straight track with hangers L=400 mm 146 mtrs

• drive station 2 pc

• tension station 1 pc

• chain lubrication station 1 pc

• drawing of the track supporting structure 1 set

Specifications

| Manufacturer | Wagner |

| Year | 2010 |

| Condition | Used |

| Stock Number | 78566 |